Goodmorning to the nature’s lovers !

To save the word and making a better place, just make a cell, and make a big change ! So in this article, I’ll present you briefly tape casting method of deposition used to make anode. Very easy, you melt the ceramic powder to a mixture to make a ink. The advantage of having a paste is to have a flexible paste which will be easy to manipulate.

So in this article, I’ll present you briefly tape casting method of deposition used to make anode. Very easy, you melt the ceramic powder to a mixture to make a ink. The advantage of having a paste is to have a flexible paste which will be easy to manipulate.

Lets see the composition of this ink :

- A solvent (Ethanol for example) wich permet to assure the homogeneity of the suspension.

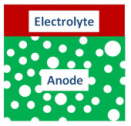

- The powder of the anode. is commonly made of a mix of YSZ (ceramic material) and nickel powder. YSZ permit the stability in high temperature, and the transport of proton H+ throw the anode until the electrolyte. Nickel is a conductive material who help hydrogen to get oxidized and to conduct electrons to the current collectors.

- The plasticizer permit to have a flexible paste at the end of the work.

- A dispersing agent permits to prevent agglomeration of particuls

- The bender assures the solidity of the paste.

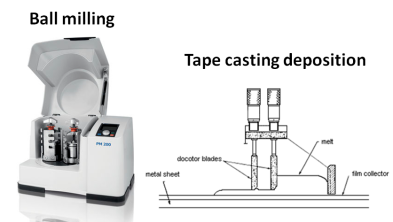

This mixture must be mixed in a planetary ball milling as shown in the following picture :

Once prepared, the ink is deposed on a flat support by squeegees. After the choice of the composition of the ink, this operation is the second crucial phase of the process, if you spray the ink to fast, bubbles risk to get captured in the ink and to deteriorate it.

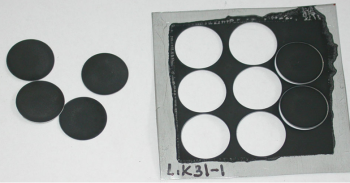

Then we have to wait the film to get dry. A good control of the atmosphere and temperature is necessary to prevent crackles appearance.

At the end of the process, the deposition is sufficiently flexible to be cut-and-dried. The following picture show the result of anode made by tape casting :

In the following article, we’ll see how to depose the electrolyte membrane on the anode.